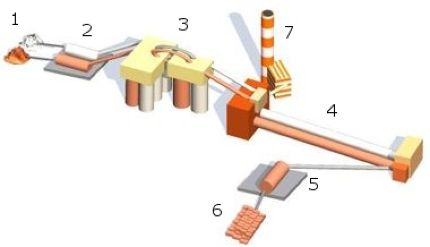

Calcium aluminate cements (e.g. GÓRKAL 40, GÓRKAL50+) are made from two materials: bauxite and limestone.In high alumina cements (e.g. GÓRKAL 70, GÓRKAL 80) bauxite is replaced with alumina.In the process of production, pre-mixed raw materials are ground, and the slurry obtained is collected in tanks.Depending on the desired type of cement, we make corrections to the premix to obtain an approved slurry, consistent with the requirements of the technological process.Thus obtained intermediate product is transported to a rotary kiln.

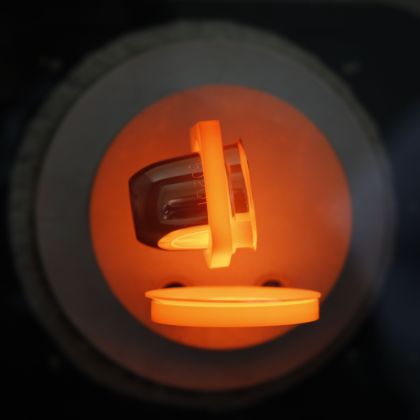

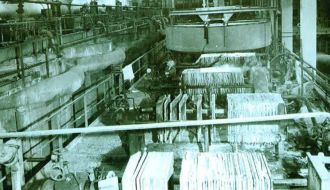

The main stage of the production process, sintering is carried out in rotary kilns with a length of 85 metres, fired by natural gas, the most "green" energy carrier.This method allows us to achieve a very homogeneous product with the desired mineralogical composition.As a result of sintering the slurry, we obtain clinker, which, after the properly conducted cooling process and after confirming the requirements as to the parameters, using physico-chemical testing, is transported to a grinding mill.Grinding is carried out in rotary ball mills, which use grinders with an increased grindability index.The cement resulting from the grinding process is stored in silos, made of both steel and concrete.

In order to ensure high quality of the cement and to eliminate the risk of preparing a product inconsistent with the specifications, at every stage of the production process, semi-finished products are inspected in our laboratory as well as in external laboratories.The finished product, GÓRKAL cement, undergoes another physico-chemical analysis and mechanical analysis.After confirming the high quality, our cement is packed into packaging in accordance with the Buyer's requirements.Properly packaged and stored, chemically pure GÓRKAL cements in practice retain their properties for up to 12 months.

Tomasz Zając

t.zajac@gorka.com.pl

1911

1911  1913

1913 1928

1928 1945

1945 1960

1960  1970

1970  1977

1977  1994

1994  2000

2000  2004

2004  2009

2009  2011

2011  2013

2013  2014

2014  2015

2015  2015

2015  2016

2016  2017

2017  2018

2018